24 Nov, 2025

Semi-slick tires may look straightforward from the outside—minimal tread, wide shoulders, and a sticky surface ready for motorsport abuse—but the compounds inside them are far more sensitive than most drivers realize. And every winter, that sensitivity reaches its limit.

Below is the real technical explanation behind why semi-slick tire production pauses, not merely slows, during winter months.

Semi-slick formulas act a lot like warm honey: smooth, elastic, and easy to shape at ideal temperatures—but once the cold sets in, the same compound behaves like refrigerated butter.

When winter begins:

>polymers stiffen

>oils blend poorly

>silica dispersion becomes inconsistent

>viscosity rises sharply

Even small deviations in uniformity translate into real-world grip differences.This is why factories begin tightening production volumes at the first sign of seasonal temperature shifts.

This is the heart of the issue—something only manufacturers truly understand. If semi-slick tires were wine, then temperature and humidity would be their cellar; one wrong condition changes everything.

>silica refuses to disperse uniformly

>viscosity increases

>resin systems activate slower

>oils resist blending

It’s like trying to stir butter fresh from the refrigerator—technically possible, practically miserable. Normalized Maximum Principal Stress vs Grading Coefficient

2. Humidity Interferes With Vulcanization

Vulcanization is a chemical handshake between sulfur systems and polymers. Humidity disrupts this handshake, causing:

Semi-slick compounds are so reactive that a tiny imbalance creates a huge performance defect.

3. Cooling Distorts Layer Bonding

A semi-slick’s tread cap is thin and extremely sensitive to temperature. In winter, the cap cools faster than the underlayers, creating internal stresses that lead to:

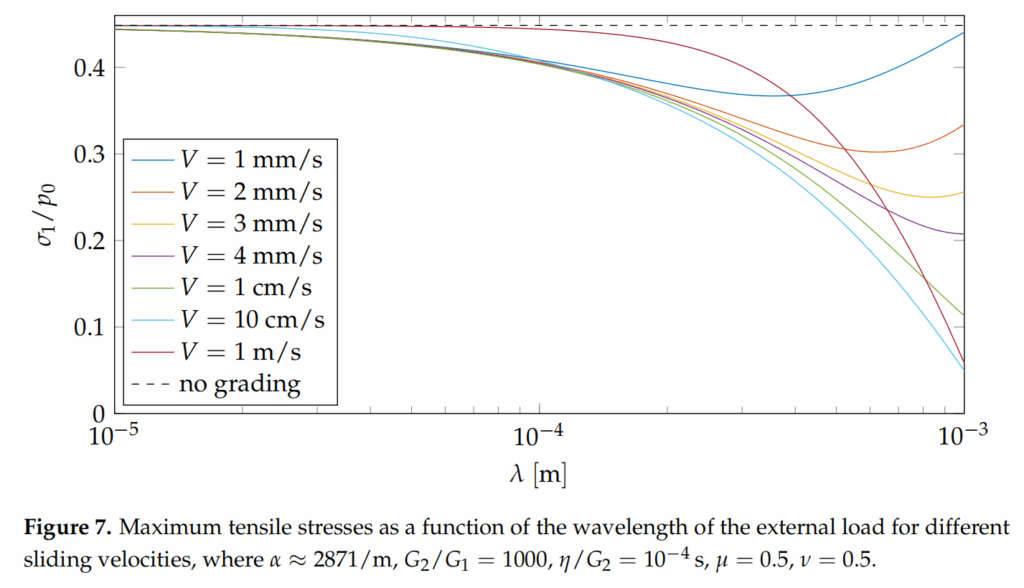

Maximum Tensile Stress as a Function of Wavelength & Sliding Velocity

4. Climate Control Costs Increase Dramatically

To maintain proper standards, factories must:

For niche motorsport tires, the cost-to-volume ratio becomes unsustainable.

Thus, many factories strategically pause production until stability returns.

Natural rubber plantations enter “wintering season,” lowering output. Material costs rise. Factories naturally prioritize high-volume commercial tires rather than niche semi-slicks.

Racing calendars slow down, track days decline, and dealers reduce orders.

Production schedules follow the market.

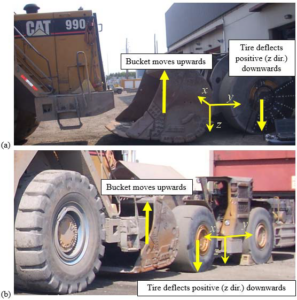

ie. Most 2025 F1 races occur in each region’s warmer season.

Manufacturers use winter downtime to perform:

Performance tire molds often get their service during this period.

Semi-slick compounds dislike:

To ensure customers receive fresh, consistent tires, manufacturers prefer producing semi-slicks closer to the racing season.

Semi-slick tire production pauses in winter not because factories slow down, but because the materials demand absolute precision.

Cold air, humidity swings, raw material seasonality, and motorsport demand all influence production—but the central reason remains the same:

High-grip rubber chemistry performs best when manufactured under warm, stable environmental conditions.

By aligning production with seasonal stability, manufacturers ensure that every semi-slick—whether for motorsport, drifting, time attack, or high-performance imports—delivers the consistency and grip that drivers depend on.

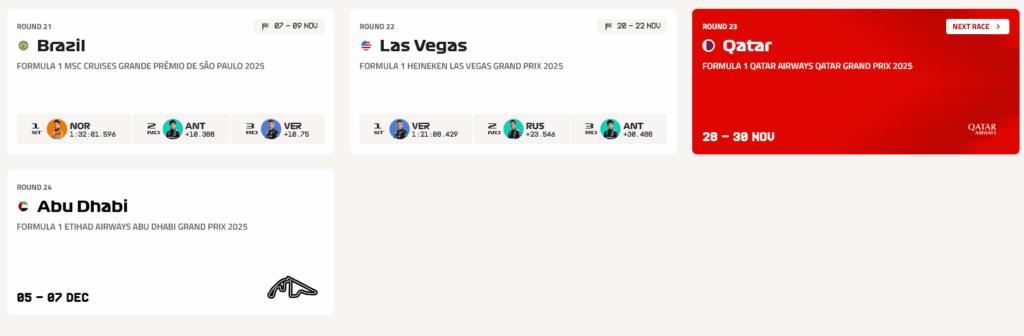

Figures Source: Figures 4 and 7 are adapted from “Temperature Gradients in Tire Rubber Can Reduce/Increase Tensile Stresses and Hence Wear and Fatigue”, Lubricants, 13(7), 294 (2025), by Leroy & Ciavarella, published under CC BY 4.0.

As vehicle cabins become quieter, tire noise has become one of the main sources of unwanted sound, especially at medium and high speeds. Noise-reducing tires are developed to address this issue directly at the tire–road interface, where most road noise is generated. Decibel scale: from quiet to road noise (Source: Continental) Where Tire Noise Comes FromFrom […]

Discover More

This research strives to enhance the safety of multi-piece wheel assemblies as injuries and fatalities are associated with their failure, yet information on this topic is limited.Experiments were performed to determine mechanical performance and planar deformation characteristics of several tires to aid in numerical model development. For a 29.5-29 tire, observations included determining vertical versus […]

Discover More