It is difficult to separate solid tire from its rim, so an equipment is necessary to achieve this task. The tool that separates the solid tire from the rim is called a “hydraulic tire press machine”, or “Tire press” for short.

Definition: hydraulic tire press machine is a kind of equipment that uses hydraulic pressure to assemble and disassemble wheels and Solid tires.

How it works: It works by applying hydraulic pressure to the tire and rim. The machine clamps the tire onto the rim and then applies pressure to force the tire onto the rim. Then, the pressure is applied evenly around the circumference of the tire. This ensures that it is properly seated and balanced.

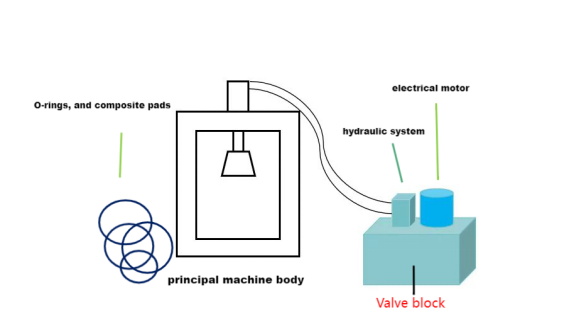

Structure

Generally speaking, the tire press machine is composed of a principal machine body, a hydraulic system (including hydraulic pump, oil states, oil tanks, electrical boxes, valves), Valve block (electronic reversing valves, pressure holding valves, relief valves), electrical motor, and its corresponding tooling molds, O-rings, and composite pads.

Classification

Common hydraulic tire press

Common machines are fixed somewhere in the factory for everyone to work on.

Advantages: Larger power range

Disadvantages: large size, inconvenient to move

Mobile hydraulic tire press

The mobile tire press is composed of two parts, the car body and the tire press. You can see this machine as a vehicle mounting the press machine.

Advantages: Mobile, more flexibility

Disadvantages: Weaker power range due to volume limitations, generally below 160T.

Specification

It is necessary to understand the main parameters of the machine before buying or using it.

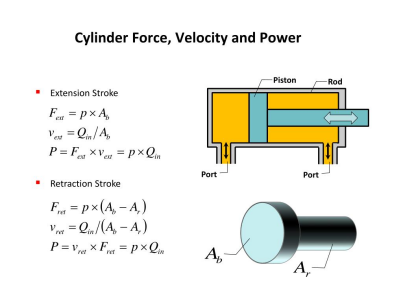

Cylinder nominal force: the maximum pressure of the hydraulic press, under normal circumstances, the actual working pressure can not exceed this value, which is related to the system pressure and the size of the cylinder piston. Generally speaking, the thicker the cylinder wall and the higher the strength of the material used, the higher the oil pressure that the cylinder can withstand.

The unit of cylinder nominal force is KN, which can also be converted into Ton. (1000KN=100T) For example, 1600KN can also be expressed as 160T.

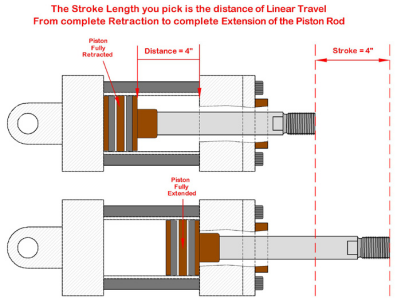

Cylinder stroke: The maximum length of the cylinder can be extended is determined by the forming height, the larger the stroke, the greater the molding cycle of the equipment.

System pressure: The system pressure of different manufacturers is also different, some are 25MPa, some are 31.5MPa, which is related to the hydraulic pump of the hydraulic system of the equipment. The higher this value, the smaller the cylinder size will be.

Motor power: power refers to the electrical energy consumed by electrical appliances per second, usually indicated on the nameplate of electrical appliances, in watts (W) or kilowatts (kW) Generally speaking, the power of a 120T tire press is 5.5KW, and the power of a 200T tire press is 7.5KW

Rated flow: The current of the motor when it is working normally (at the rated voltage).

Voltage: The general voltage of the machine, generally 230V. Voltage can be customized according to customer’s requirements. For example, if the system grid voltage in the customer’s country is 205V, the machine voltage should be 205V instead of 230V.

Current: The current of the motor in the machine, generally 60Hz. The current can be customized according to customer needs. For example, if a customer needs a 50hz machine, he should customize the corresponding 50Hz motor after understanding the situation.

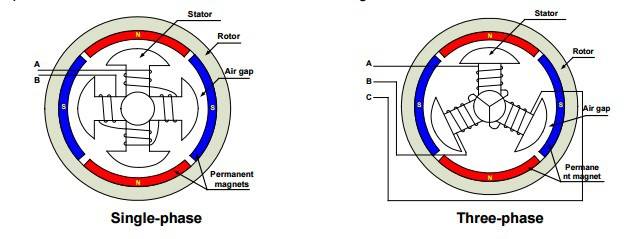

Phase: The phases of an asynchronous motor, generally single-phase and three-phase. The “phase” in the number of motor phases refers to the number of phase wires (also known as live wires) used. A three-phase motor uses three live wires.

There is a machine specification as example,

-Phase: 3 phase

-Motor power: 7.5KW

-Current: 60HZ

-Voltage: 230V

-Cylinder stroke: 800mm

-System pressure:25MPA

-Nominal force of cylinder: 2000KN/200T

Pressure and corresponding applicable tire size (maximum rim)

120Ton: Suitable for pressing 15-inch solid tires

160Ton: Suitable for pressing 16-inch solid tires

200Ton: Suitable for pressing 20-inch solid tires

250Ton: Suitable for pressing 25-inch solid tires

300Ton: Suitable for pressing 30-inch solid tires

350Ton: Suitable for pressing 33-inch solid tires

Notice

The following are some precautions during the installation and use of the machine

1. The solid tires here only refer to general solid tires, not press-on solid tires. Due to the special construction of press-on solid tires, a machine withmuch greater pressure than ordinary solid tires is required to separate the tire and rim.

2.Wiring must be installed as required. Plugs must not be used, valve type switches must be used

3.After the initial installation, the corresponding volume of engine oil must be added according to the manual requirements before starting.

4.During the operation, if any fault display or abnormal sound is found, the machine should be stopped immediately for inspection. If the problem is related to the equipment itself, it should be reported to a professional immediately, and it is not allowed to disassemble it by yourself.

5.During operation, tools and accessories should be handled with care. After use, the power should be turned off, the tools and accessories should be returned to their original positions, and debris and stolen objects on the tire changer should be cleared away.

6.Clean and lubricate all parts of the tire changer regularly, and check whether the working pressure gauge is normal.

If you still have some questions, we have professional team to assist you at anytime!