30 Dec, 2025

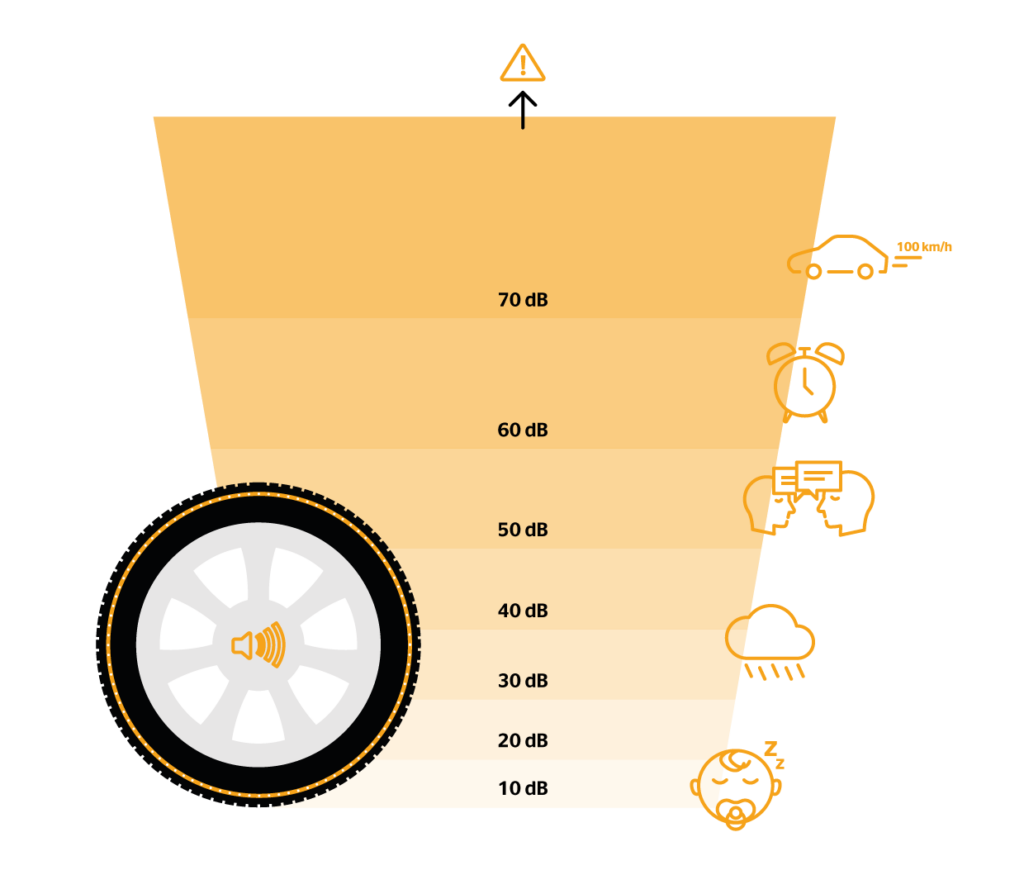

As vehicle cabins become quieter, tire noise has become one of the main sources of unwanted sound, especially at medium and high speeds. Noise-reducing tires are developed to address this issue directly at the tire–road interface, where most road noise is generated.

Decibel scale: from quiet to road noise (Source: Continental)

Where Tire Noise Comes From

From a technical standpoint, tire noise mainly originates from four mechanisms during rolling

Tread air pumping

When tread blocks contact the road, air trapped in the grooves is compressed and released repeatedly. This creates pressure fluctuations and airborne noise. Groove width, depth, and edge shape have a direct impact on this effect.

Pattern excitation

As tread blocks strike the road surface, they generate impact forces. If block spacing is uniform, these forces excite specific frequencies, resulting in a strong and continuous noise peak.

Structural vibration

The tire tread, belt, and carcass deform cyclically during rotation. Without sufficient damping, this vibration is transmitted through the wheel and suspension into the vehicle cabin.

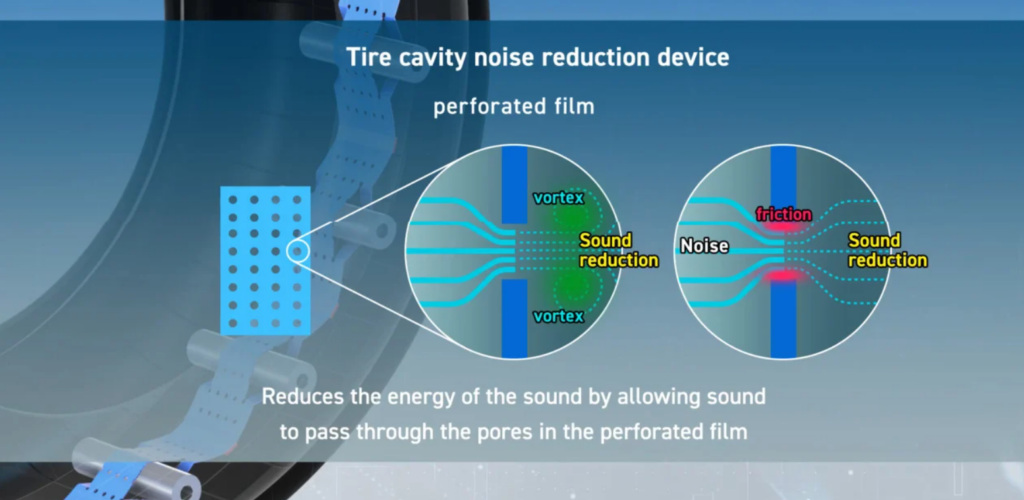

Cavity resonance

The air volume inside the tire acts as a resonance chamber. At certain speeds, internal air vibration amplifies noise in frequency ranges that are particularly noticeable to human hearing.

Noise-reducing tires are designed to control these noise sources rather than attempting to eliminate sound entirely.

Variable pitch tread design

Multiple tread block lengths are arranged in a calculated sequence to prevent sound energy from concentrating at a single frequency. This reduces peak noise levels and avoids the monotone “drone” common in conventional tread designs.

Michelin

Toyo

Optimized groove geometry

Chamfered edges, narrow groove openings, and auxiliary grooves are used to reduce air pumping effects. These features help control airflow behavior inside the tread pattern and lower high-frequency noise.

Rubber compound vibration control

Noise-reducing compounds are formulated with increased damping characteristics. This allows the rubber to absorb vibration during road contact while maintaining sufficient stiffness for wear resistance and structural stability.

Internal noise reduction solutions

In certain designs, sound-absorbing materials are applied inside the tire to suppress cavity resonance. These solutions target specific frequency ranges and are used selectively depending on tire size and vehicle application.

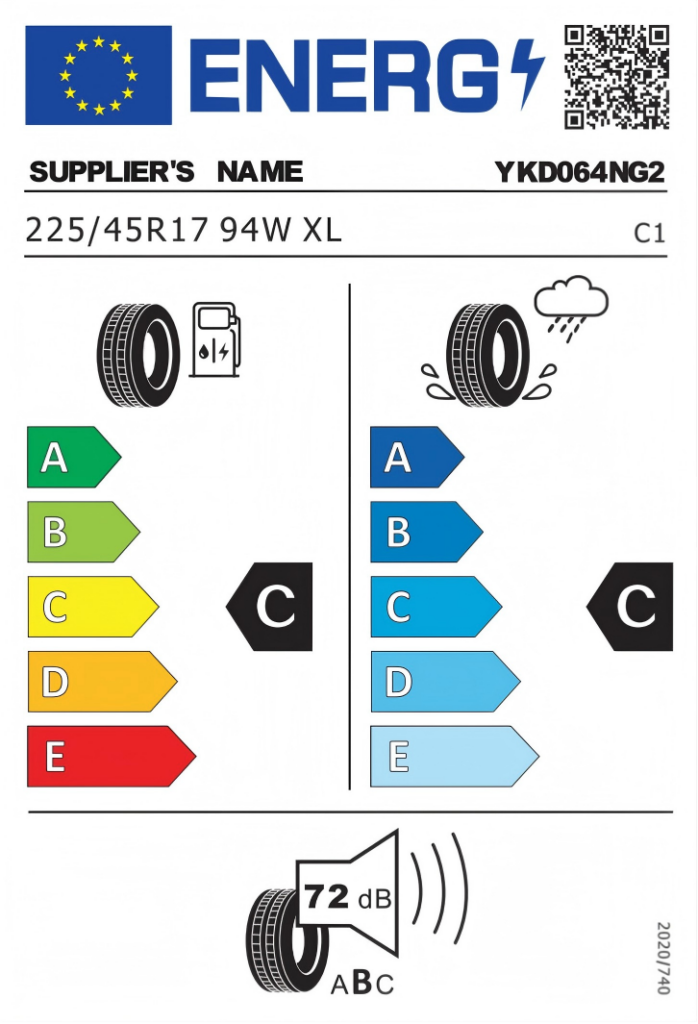

Noise Reduction and EU Labeling

Under EU tire labeling regulations, external rolling noise is measured in decibels (dB) during pass-by testing. Noise-reducing tires are typically engineered to achieve lower external noise ratings through tread and air-flow optimization.

It is important to note that:

* EU labels reflect external noise, not cabin noise

* Internal comfort improvements may not be fully represented by dB values alone

In practical use, noise-reducing tires generally provide:

Actual results depend on road surface, vehicle insulation, suspension design, speed, and tire pressure. Under comparable conditions, noise-reducing tires consistently show lower perceived noise levels than conventional designs.

As vehicle cabins become quieter, tire noise has become one of the main sources of unwanted sound, especially at medium and high speeds. Noise-reducing tires are developed to address this issue directly at the tire–road interface, where most road noise is generated. Decibel scale: from quiet to road noise (Source: Continental) Where Tire Noise Comes FromFrom […]

Discover More

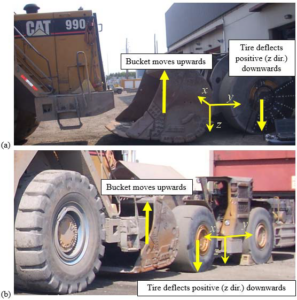

This research strives to enhance the safety of multi-piece wheel assemblies as injuries and fatalities are associated with their failure, yet information on this topic is limited.Experiments were performed to determine mechanical performance and planar deformation characteristics of several tires to aid in numerical model development. For a 29.5-29 tire, observations included determining vertical versus […]

Discover More