01 Nov, 2025

Only specially trained personnel should mount tires. Failure to comply with these tire demounting/mounting safety precautions can cause the bead to break and the assembly to burst with sufficient force to cause serious injury or death.

1.Always deflate tire completely before removing lock or side rings.

2.Never use rim parts of different manufacturers or different size.

3.Never mount tires on rims which are damaged or not smooth and clean.

4.Always clean and inspect rim. Lubricate beads[and rim flanges for tubeless 5. tires],tube and rim side of flap with an approved rubber lubricant.

5.Always be sure that rim components are properly seated before inflating.

6.Always use an extension hose with gauge and clip-on chuck.

7.Always use a safety cage or other restraining device when inflating the tire to seat the beads and/or inflating the tire to normal operating inflation pressure.

8.Never inflate beyond 275kPa(2.75 bar, 40 psi)to seat the beads.

9.Never stand, lean or reach over the assembly during inflation.

10.After beads are fully seated, adjust to vehicle manufacturer’s recommended inflation pressure.

11.Never mount radials on the same axle with bias tires. Follow vehicle manufacturer’s recommendations.

12.Tires must be removed when remaining tread depth reaches regulated measurement in your jurisdiction.

13.Moisture in tire can damage the casing. Stored tires in a dry area. Dry interior before mounting. Inflate with dry air.

As vehicle cabins become quieter, tire noise has become one of the main sources of unwanted sound, especially at medium and high speeds. Noise-reducing tires are developed to address this issue directly at the tire–road interface, where most road noise is generated. Decibel scale: from quiet to road noise (Source: Continental) Where Tire Noise Comes FromFrom […]

Discover More

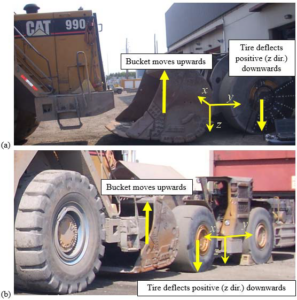

This research strives to enhance the safety of multi-piece wheel assemblies as injuries and fatalities are associated with their failure, yet information on this topic is limited.Experiments were performed to determine mechanical performance and planar deformation characteristics of several tires to aid in numerical model development. For a 29.5-29 tire, observations included determining vertical versus […]

Discover More