For decades, diesel-powered wide-body dump trucks have dominated open-pit mines worldwide. Their robustness and long operating range made them the default choice, but rising fuel costs and increasing maintenance burdens are gradually reshaping how operators evaluate haulage equipment.

Rather than just comparing top-line performance or upfront costs, many procurement teams now look closely at operating cost structure, tracking how energy use, maintenance needs, and system complexity influence long-term fleet economics.

Diesel Platforms

Conventional diesel trucks, such as the CAT 793F and Komatsu 830E, remain widely used, especially in remote mines with established fuel logistics. Operators report that maintenance demands rise significantly as emission systems age.

Hybrid and range-extended solutions are increasingly positioned as transitional options. By combining internal combustion engines with electric drive components, these platforms aim to reduce fuel consumption while maintaining operational flexibility. In practice, operators often view hybrids as a risk-mitigated step toward electrification, especially in mines where haul distances vary significantly or charging infrastructure is still under development.

Fully electric wide-body dump trucks introduce a fundamentally different operating model. Higher drivetrain efficiency and fewer moving mechanical components translate into lower routine maintenance demand. At the same time, performance is closely linked to site conditions such as power supply stability, ambient temperature, and duty cycle planning—factors that play a decisive role in real-world cost outcomes.

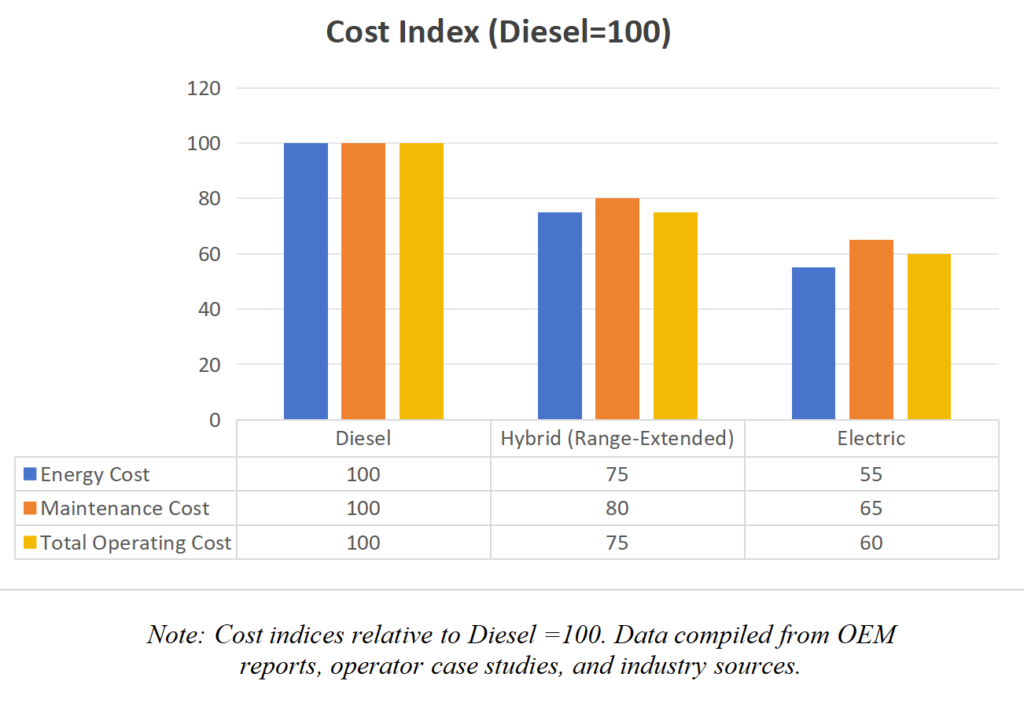

Figure 1. Operating Cost Comparison of Mining Wide-Body Dump Trucks

This indexed comparison illustrates the relative operating cost structure of diesel, hybrid (range-extended), and electric wide-body dump trucks, with diesel platforms set as the baseline (Cost Index = 100).

From an operator’s perspective, electric platforms consistently demonstrate advantages in energy efficiency, particularly in repetitive haul cycles typical of open-pit mines. Reduced reliance on lubricants, filters, and complex powertrain components contributes to lower routine maintenance demand. Hybrid solutions show measurable improvements over diesel platforms, although the magnitude of cost reduction varies with duty cycle stability and system utilization.

While the indexed cost comparison highlights clear structural differences, it does not imply that a single powertrain solution is universally optimal. Field experience from mining operations indicates that operating cost performance is strongly influenced by local conditions. Factors such as haul road gradients, shift intensity, ambient temperature, and charging or power availability can significantly affect realized savings.

In colder climates or in operations with continuous multi-shift schedules, for example, energy management strategies and infrastructure planning become critical to achieving the theoretical advantages of electrified platforms. As a result, many operators evaluate powertrain selection not as a binary decision, but as part of a phased fleet strategy aligned with site development plans.

Across the industry, the shift toward electrification is less about rapid replacement and more about cost structure optimization over the equipment lifecycle. Diesel platforms continue to play a role in specific operating environments, while hybrid and electric trucks are increasingly integrated where conditions allow for predictable duty cycles and stable energy supply.

For decision-makers, the key takeaway is not the absolute magnitude of cost reduction, but the growing ability to manage and forecast operating costs with greater precision. As powertrain technologies mature and operational data accumulates, operating cost transparency is becoming a central factor in fleet planning and long-term mine economics.

The evolution of wide-body dump truck powertrains reflects a broader shift in mining equipment evaluation—from upfront capability toward sustained operating efficiency. Indexed operating cost comparisons provide a practical framework for understanding how diesel, hybrid, and electric platforms differ in cost structure, while leaving room for site-specific realities.

As mines continue to balance productivity, reliability, and cost control, operating cost analysis will remain a critical reference point in selecting the most appropriate haulage solution for each stage of operation.